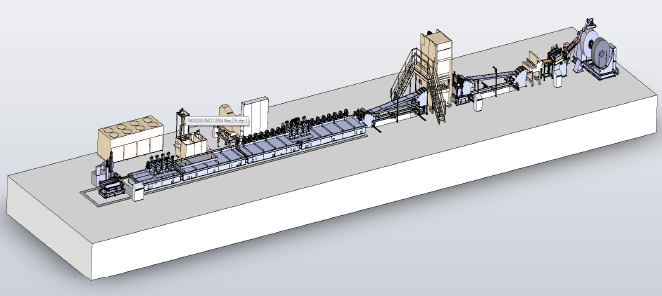

OMCO’s roll forming mills can efficiently produce large volumes of custom welded tubes in nearly any profile. The line incorporates a 330-ton pre-punch press, a 3.5″ rafted roll forming mill and a150 kW high frequency welder with integrated eddy current monitoring.

In addition to custom shapes, our facility can provide cost-effective welded tubes that have slots or holes in any configuration.

OMCO’s capabilities are particularly attractive for customers that require the efficient manufacturing of high volume closed welded shapes; whether it’s:

- High volumes of non-standard closed welded shapes that are unavailable from traditional “tubers,” or

- High volumes of standard welded tubes that require extensive or unusual punching, notching, slotting or other fabrication or finishing operations.

Custom welded tubes are used in a variety of products, including:

- Material handling systems

- ROPS and FOPS structures

- Torque tubes

- Transportation industry components

Our mills include:

- Rafted, 24 pass roll forming mill with 3.5″ diameter spindles

- Capable of rolling material up to a maximum thickness of 0.250″

- Inline 150 kW high frequency welding system

- 330-ton pre-punch press

- Inline eddy current weld monitoring system

- High-capacity cut-off shear

These top-of-the-line features allow OMCO to cost-effectively produce high quality custom welded tubes in a wide range of sizes and material thicknesses.