[fusion_builder_container type=”flex” hundred_percent=”no” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” overlay_color=”” video_preview_image=”” border_color=”” border_style=”solid” padding_top=”” padding_bottom=”” padding_left=”” padding_right=””][fusion_builder_row][fusion_builder_column type=”2_3″ layout=”1_1″ background_position=”left top” background_color=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”false” min_height=”” hover_type=”none” link=”” border_sizes_top=”” border_sizes_bottom=”” border_sizes_left=”” border_sizes_right=”” first=”true” spacing_right=”2.6666666666666665%”][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”” rule_size=”” rule_color=”” hue=”” saturation=”” lightness=”” alpha=”” content_alignment_medium=”” content_alignment_small=”” content_alignment=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” class=”” id=”” margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” fusion_font_family_text_font=”” fusion_font_variant_text_font=”” font_size=”” line_height=”” letter_spacing=”” text_transform=”” text_color=”” animation_type=”” animation_direction=”left” animation_color=”” animation_speed=”0.3″ animation_delay=”0″ animation_offset=”” logics=””]

Custom Roll Forming Capabilities | Roll Forming Services

OMCO’s commitment to quality is unparalleled, as is our dedication to 100% on-time delivery, continuous improvement, and the principles of Lean Manufacturing. Our capabilities are broad, so you can choose the most appropriate materials and the most exact specifications in roll forming your parts. Below is a list of metals and grades that we use, along with an overview of our facilities, our manufacturing and engineering capabilities, and our quality assurance procedures.

Metals

- Aluminum

- Cold rolled

- Copper

Grades

- Commercial Steel

- Drawing Steel

- Structural Steel

Facilities

With six facilities throughout the U.S., OMCO can assure your roll forming parts are completed on time. By adjusting our production schedules, we can normally accommodate increases in your roll forming requirements quickly.

Engineering

Our engineering capabilities are the foundation of the organization, from the technical sales group to the management team. The product engineering group provides detailed recommendations and design analysis for all projects that are submitted for quotes, and the manufacturing engineering group assures that every design is manufactured seamlessly and cost effectively.

Manufacturing

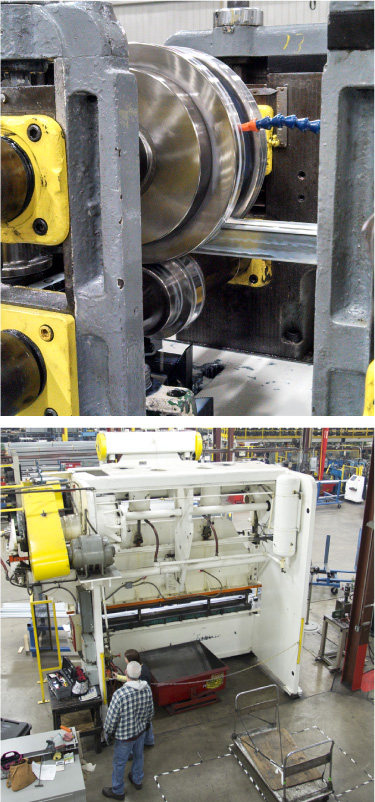

With over 50 roll forming mills across our six locations, OMCO’s manufacturing capacity exceeds 500,000 feet per shift. Complementing our roll forming lines are numerous punching, piercing, and stamping presses as well as many other metalworking operations. Each year, OMCO continues to add new capabilities to its manufacturing operations in order to better serve our growing and increasingly diverse customer base.

Quality Assurance

The culmination of all of our efforts to establish a geographically diverse manufacturing presence, employ the industry’s best engineering staff, and incorporate a wide range of value-added manufacturing operations is the superior quality of the product delivered to our customers. Quality products begin with robust engineering designs, reliable and repeatable manufacturing operations, and a desire to produce and deliver the best possible part every day.

[/fusion_text][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ background_position=”left top” background_color=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”true” min_height=”” hover_type=”none” link=”” border_sizes_top=”” border_sizes_bottom=”” border_sizes_left=”” border_sizes_right=”” first=”false” spacing_left=”1.3333333333333333%”][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”” rule_size=”” rule_color=”” hue=”” saturation=”” lightness=”” alpha=”” content_alignment_medium=”” content_alignment_small=”” content_alignment=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” class=”” id=”” margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” fusion_font_family_text_font=”” fusion_font_variant_text_font=”” font_size=”” line_height=”” letter_spacing=”” text_transform=”” text_color=”” animation_type=”” animation_direction=”left” animation_color=”” animation_speed=”0.3″ animation_delay=”0″ animation_offset=”” logics=””] [/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]