OMCO Advantage

Why OMCO?

Largest Custom Roll Former in the United States

Founded in 1955, OMCO is the largest custom roll former in the United States. We manufacture highly engineered shapes for many applications across a wide range of industries. Components for truck bodies, trailers, material handling systems, solar panel frames and supports, conveyors, escalators, and many more products are manufactured cost effectively using roll forming technology.

As a leader in the roll forming industry, OMCO has spearheaded many innovations, allowing us to produce the highest quality parts possible. We continuously invest in our facilities and technologies to increase our level of automation, reduce waste, and minimize changeover time.

In addition, OMCO’s extensive knowledge and experience with roll forming and related manufacturing operations provides a highly valued service to our customers. Our engineering staff can assist in redesigning a part or assembly to incorporate additional manufacturing operations, reduce assembly time, or improve durability.

OMCO Advantage

Manufacturing Power Now Yours!

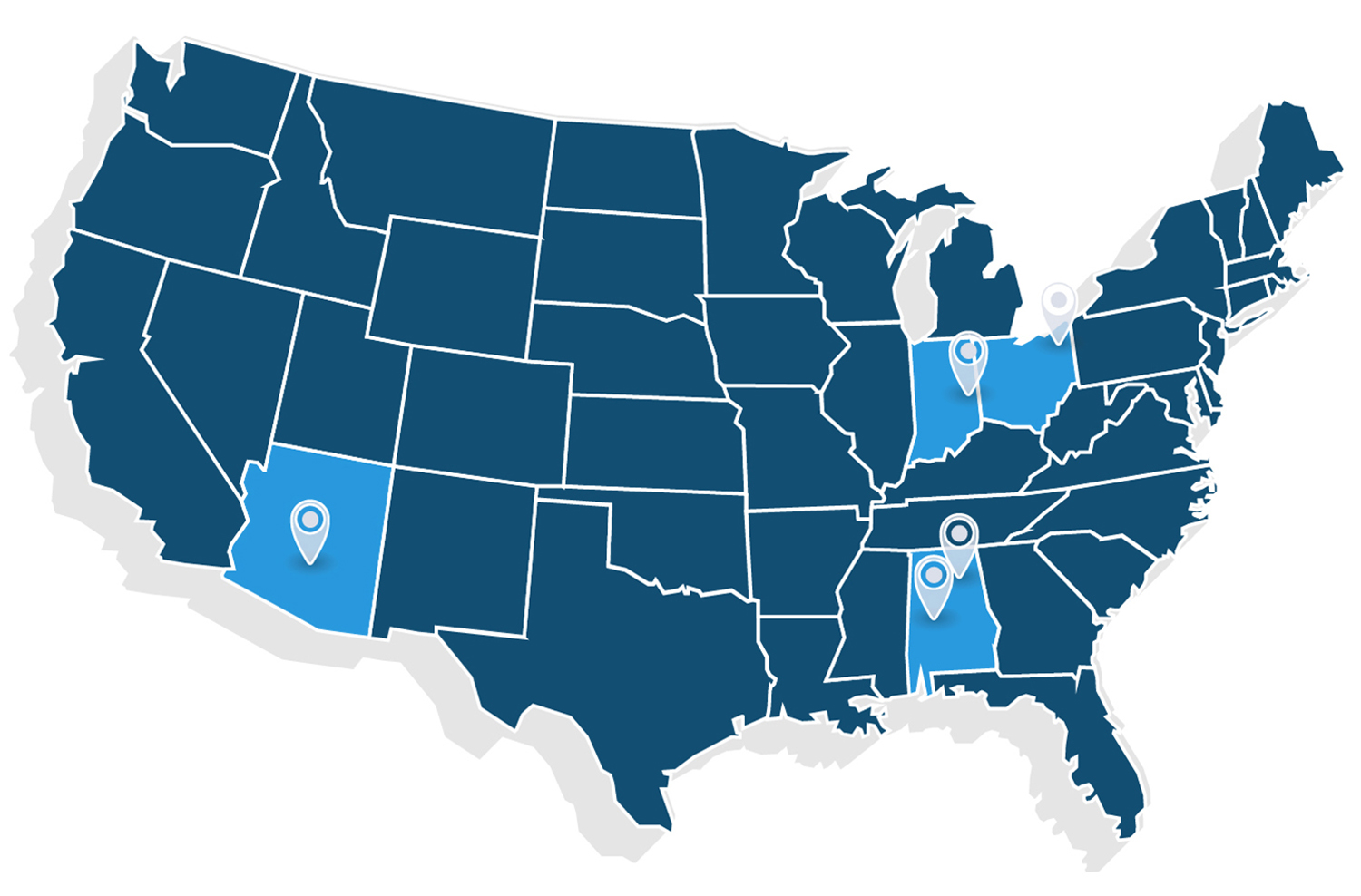

OMCO’s five manufacturing facilities represent 700,000 square feet of manufacturing space and house more than 50 active roll forming mills. Our nationwide footprint spans the United States, from Ohio to Arizona with each location incorporating common design parameters and performing a wide variety of supplemental metal forming operations.

OMCO’s broad geographic footprint and substantial manufacturing capacity gives them the ability to adjust production schedules to accommodate increases in your roll forming requirements quickly. Roll form benefits of supply chain efficiency and flexibility right in the hands of customers, while delivering superior products on-time, cost effectively, to them throughout North America.

OMCO Advantage

Cost-Reducing Services

Engineering Support

- Product design improvements

- Design-for-manufacturability

- Prototyping services

- CAD/CAM support

- Finite Element Analysis

Field Support

- On-site training

- Field technical support

Manufacturing Services

- A wide range of value-added manufacturing operations in conjunction with roll forming to help reduce the total cost of a part or assembly.

- Custom assembly that provides a single source for entire assemblies, reducing manufacturing, shipping and handling costs.

- Custom packaging

Logistics Services

- Direct shipment of orders

- JIT delivery

- Regional manufacturing facilities

OMCO Advantage

Custom Roll Forming Capabilities

Below is a list of metals and grades that we use:

Metals

- Aluminum

- Cold rolled

- Copper

Grades

- Commercial Steel

- Drawing Steel

- Structural Steel

Core Values

Leadership

Service that guides and inspires, unlocking the best out of production, business, and partnership.

Integrity

Trustworthy and responsible professionalism in everything we do throughout the organization.

Positivity

Proactively fostering a winning environment of inclusion and assurance leads to success.

Teamwork

Building better through healthy collaboration.

Purposeful

Cultivating solutions is intentional at

OMCO Solar.

Leadership

Service that guides and inspires, unlocking the best out of production, business, and partnership.

Integrity

Trustworthy and responsible professionalism in everything we do throughout the organization.

Positivity

Proactively fostering inclusion, participation, and success.

Teamwork

Building better through healthy collaboration.

Purpose

Cultivating solutions is intentional at

OMCO.