Copper Bus Bar Services

OMCO copper bus bar services help companies revolutionize the track busway systems that allow power distribution to be expanded quickly and safely across data centers. We understand facility managers often have to manage spacing as well as installation and modification of these systems to keep their data centers at peak performance, so having reliability is of the upmost importance.

At OMCO, we share that same commitment to reliability and our custom roll forming capabilities can quickly scale your copper bus bar part design into production with second-to-none volume, quality, cost, and delivery.

As society becomes more digital with the growth of AI, energy demand continues to soar in the United States. Having a trusted domestic manufacturing partner is even now more crucial towards America’s energy independence and dominance.

Here at OMCO, manufacturing power is now yours!

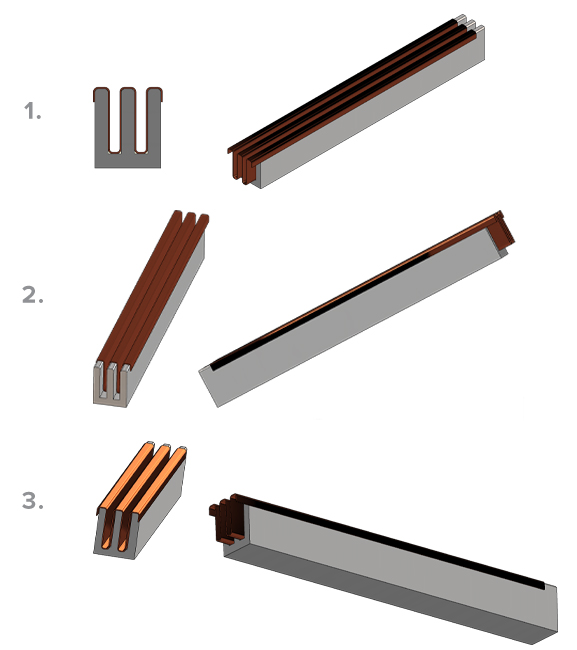

Engineering Your Part

As the largest custom roll former in the United States, our copper bus bar capabilities are engineered to meet your part specifications.

All roll form tooling is designed in-house, sourced in the USA, and maintained for life.

Benefits of Roll Forming Busbar vs. flat bars:

Customization – OMCO can create a unique profile to fit your application

Design Flexibility – Can be formed and shaped for tight tolerances

Space Efficiency – A roll formed part will enable an exact fit in your busway enclosure

Our Capabilities

- OMCO can roll form copper in multiple thicknesses, with complex cross sections, and tolerances as tight as +/- .015.

- REACH/RoHS compliant

- Part marking

- OMCO incorporates an inline flying saw for complex copper profiles, to cut without any

distortion.

Other Facility Applications

We can service other facility applications such as:

- Manufacturing

- Commercial

- Retail

- Medical

- Science