OMCO has developed tooling for basic sheet metal roll forming shapes that are common in many industries. We can also produce tooling to meet custom roll forming specifications for commercial products, including specialty products like trucks and trailers. Examples of the types of roll forming shapes we produce every day are shown in this section.

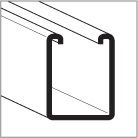

Custom Roll Formed Shapes

Our specialty is roll forming custom designed parts. Parts may be customized because of a unique profile, hole and slot pattern, additional hardware, or other specialized finishing operations.

Custom Welded Tubes

Our highly automated mill incorporates pre-punch capability and a 150 kW high frequency welder with integrated eddy current monitor.

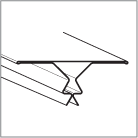

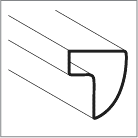

Standard Roll Formed Shapes

Some shapes are common across many industries and applications. If your part is similar to one of these, you may be able to take advantage of our in-house tooling which could significantly reduce your tooling investment.

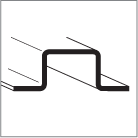

Commercial Products

The roll forming process can produce particular shapes that are used for specific applications. OMCO manufactures large volumes of these parts in custom lengths, with customized modifications for large projects or high volumes. The flexibility of using our existing tooling can result in tremendous savings for our customers. Commercial Products include Strut Channel, Dunnage Bars, and Structural Steel.

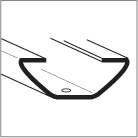

Truck & Trailer Shapes

The Truck & Trailer industry has incorporated roll formed parts in their products for many decades. OMCO has been an important supplier and partner to many of the largest manufacturers in this industry.